HOW WE DO WHAT WE DO

OUR CRAFT

SOURCING

At Tusk, we understand the importance of sourcing quality materials — not just for our customers, but for the earth, too. We select our leathers from tanneries which have earned Gold and Silver ratings from the Leather Working Group — a group which has set environmental standards for tanners and which promotes sustainable and appropriate environmental business practices within the leather industry. Knowing the origin, we then choose our leathers in person, judging their quality by touch and sight, and always keeping the end product in mind. That means that from the moment we find our source material to the moment you take a Tusk bag, wallet, or accessory home, every detail has been hand-selected with the highest quality, intention, and respect for the environment in mind.

TANNING AND DYE PROCESS

With records dating back over 4,000 years, leather tanning is the oldest industry in human history. Our prehistoric ancestors learned early on that using the hide of animals for footwear, clothes, and gear was essential to their survival. And they realized that if they didn’t find some way to preserve the raw hides, decay would set in and render the hide useless. What they discovered was the process of tanning — converting raw animal hides into supple, durable, and long-lasting leathers. Today, through processes like vegetable and chrome tanning, we’ve advanced the methods of our ancestors into more efficient and versatile practices. And, through modern techniques of dyeing, we’ve opened up the leather color palette from the neutrals of old to the rich hues and exploratory spectrum of today.

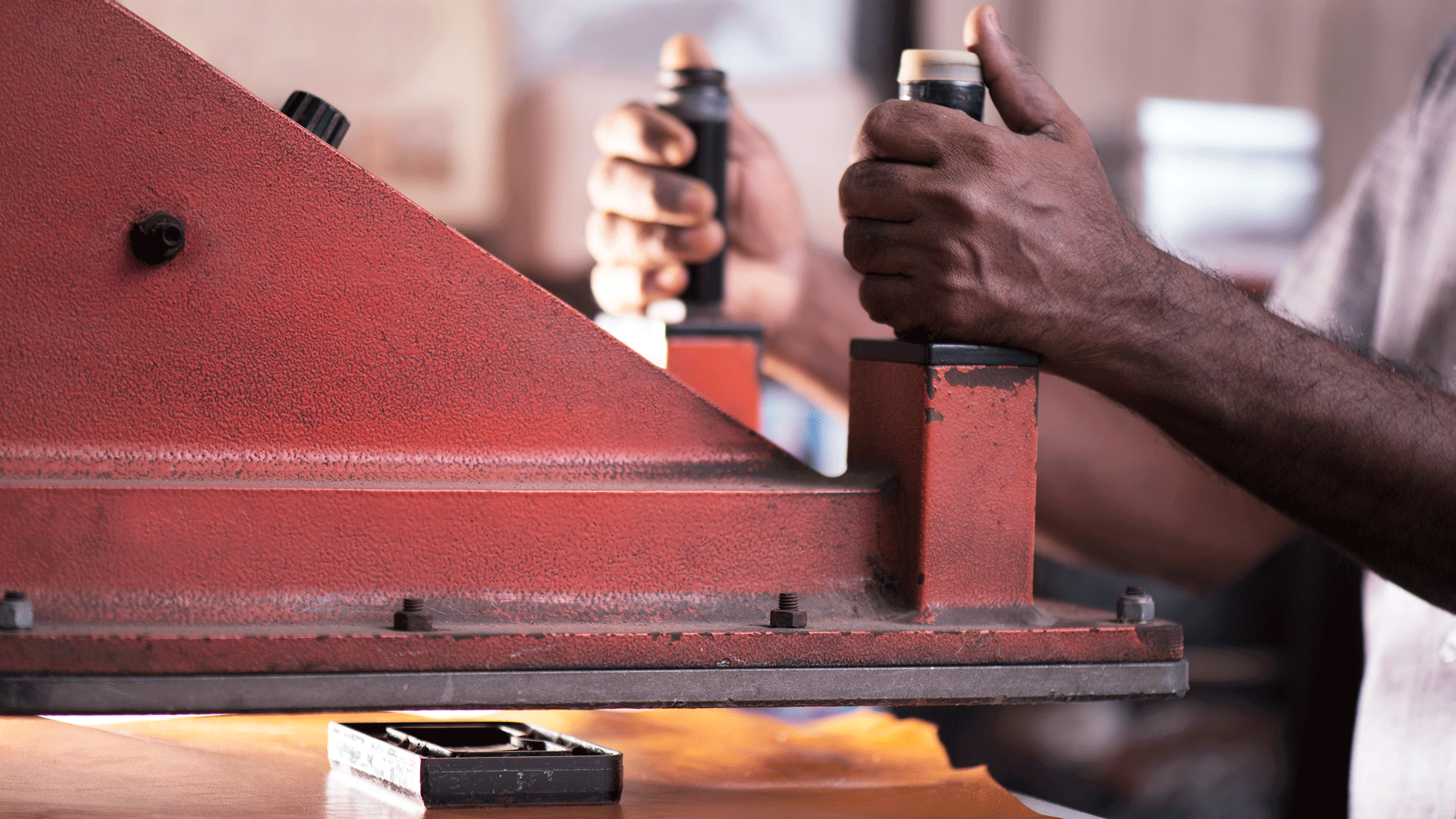

FINISHING

The final stage of the leather tanning process is finishing, and, just as modern techniques of dyeing would have fascinated our ancestors, so too would the latest technologies in finishing. Using machines or the hands of dedicated craftsmen, finishes like polishing, ironing, plating, embossing, and tumbling can alter the look of the final leather product. Leather might be polished with a velvety wheel to create a shiny surface, or it embossed to obtain a three-dimensional print, or tumbled to create a more evident grain. Or, if preferred, the leather might be finished using chemical processes that coat the leather with a natural or synthetic spray to increase color saturation or shine. Whatever the choice, the finishing process adds the final touches to the leather’s transformation.

HOW IT ALL COMES TOGETHER

From raw hide to the Tusk bag, wallet, or accessory you’ve come to love, the journey of designing and making a leather product of quality is mapped through the dedication of the craftsmen and artists who make it possible. Hand-drawn designs, a family-owned factory filled with lifelong craftsmen, and hardware from artists in Italy and Japan — Tusk products capture a world of talent in each and every detail.